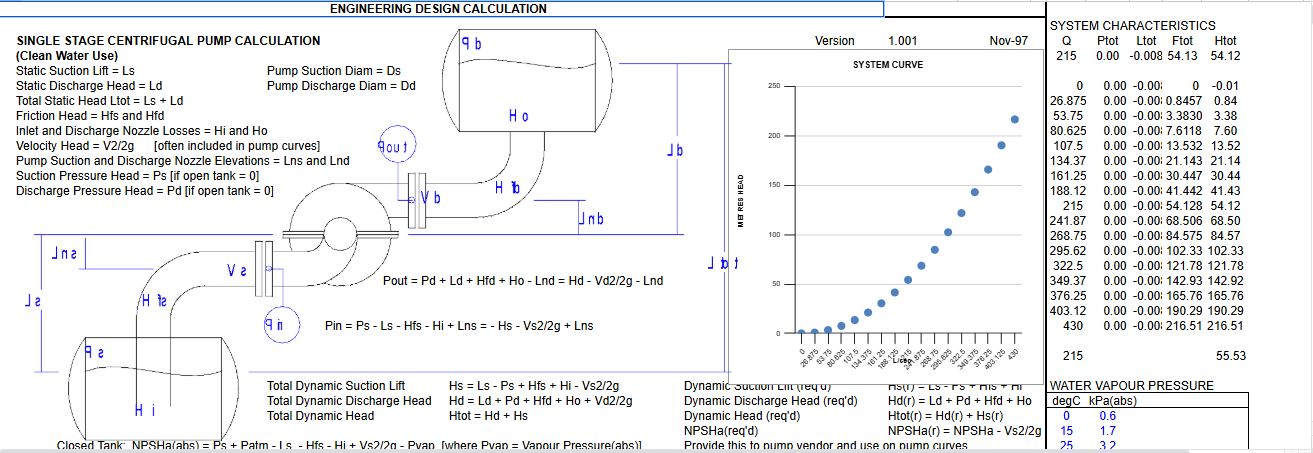

SINGLE STAGE CENTRIFUGAL PUMP CALCULATION

Performance and Design Calculations for Single-Stage Centrifugal Pumps

$12.00

A single stage centrifugal pump is designed to move fluids by converting rotational energy into hydrodynamic energy. The fundamental calculation for such a pump involves understanding the relationship between various parameters, including flow rate, head, and pump efficiency. To determine the required flow rate, one must factor in the system’s hydraulic requirements and the characteristics of the fluid being pumped. The total head is calculated by accounting for both the static lift and the friction losses within the piping system. Additionally, the specific speed of the pump is critical in selecting the appropriate impeller and casing design to ensure optimal performance. By carefully analyzing these elements, engineers can ensure the pump operates efficiently, minimizing energy consumption while meeting the necessary flow demands. Regular performance evaluations can also help maintain the pump's effectiveness over time, preventing failures and prolonging service life.