PUMP SIZING CALCULATION

Methods and Formulas for Accurate Pump Sizing Calculations

$12.00

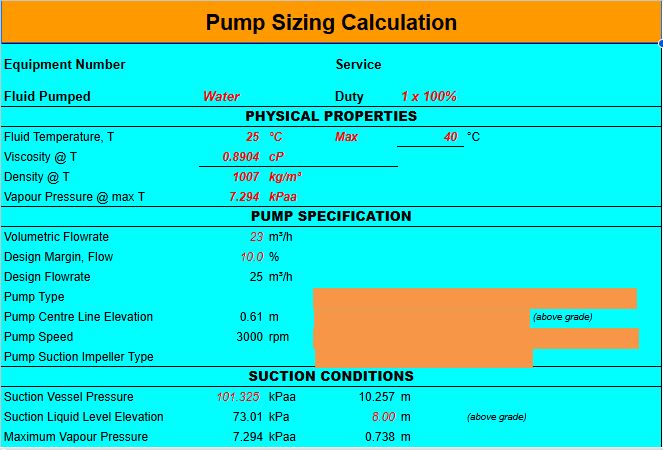

Pump sizing calculation is a critical process in ensuring that a pump system operates efficiently and effectively for its intended application. It involves determining the required flow rate and head pressure to meet the demands of the system, taking into account various factors such as fluid properties, distance, and elevation changes. Engineers must consider the specific requirements of the application, including the type of fluid being pumped and the system's overall layout. By accurately sizing the pump, one can minimize energy consumption, reduce wear and tear on the equipment, and ensure optimal performance. Additionally, it is essential to factor in safety margins and potential future changes in system demand to avoid inefficiencies. Proper pump sizing not only enhances system reliability but also contributes to cost savings in both installation and long-term operation.

Proper pump sizing is essential to ensure efficient operation and optimal performance in fluid handling systems. This process involves determining the required flow rate, head, and power to select the right pump for a given application. Factors such as fluid properties, pipe friction losses, elevation changes, and system requirements are considered in the calculations. By using standardized formulas and industry guidelines, engineers can accurately size pumps to minimize energy consumption, prevent cavitation, and enhance system reliability. This guide provides a step-by-step approach to pump sizing calculations, covering key parameters, equations, and best practices.