FILTER SIZING CALCULATION

Essential Formulas and Methods for Filter Sizing Calculations

$39.00$19.00

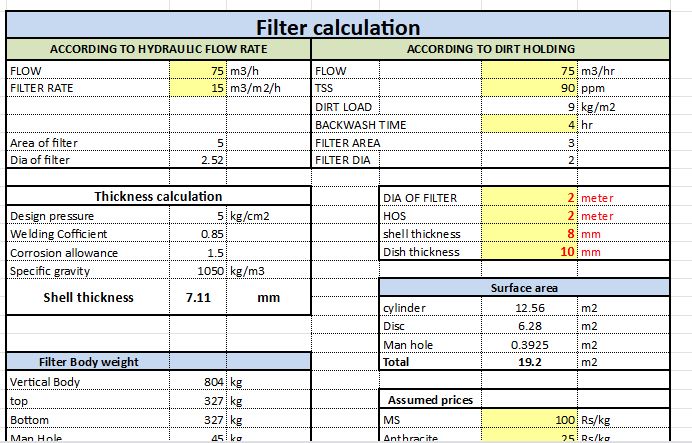

When calculating filter sizing, it's essential to consider several key factors to ensure optimal performance and efficiency. First, assess the flow rate required for your specific application, as this will greatly influence the size and type of filter needed. Additionally, take into account the type of fluid being filtered, including its viscosity and particulate load, which can affect the filter's lifespan and maintenance frequency. The desired level of filtration must also be defined; the particle size that needs to be removed will determine the filter's mesh size or pore size. Lastly, environmental conditions, such as temperature and pressure, should be factored in, as they can impact the rate of clogging and overall effectiveness. By closely analyzing these variables, one can accurately size a filter to achieve the best results while minimizing downtime and operational issues.

Filter sizing calculation is an essential process for selecting the right filter to meet the specific requirements of a filtration system. The sizing process ensures that the filter can handle the desired flow rate, effectively remove particulates, and maintain optimal performance over time. Key factors in filter sizing include the flow rate, pressure drop, type of particles to be filtered, filter media characteristics, and the system's operating conditions. Proper calculations help avoid issues like excessive wear, clogging, or inefficient filtration. This guide provides the necessary formulas, methods, and considerations for accurately sizing filters to ensure reliable and efficient system operation.