CENTRIFUGAL PUMP DESIGN CALCULATIONS

Key Formulas and Methodology for Centrifugal Pump Design Calculations

$29.00$19.00

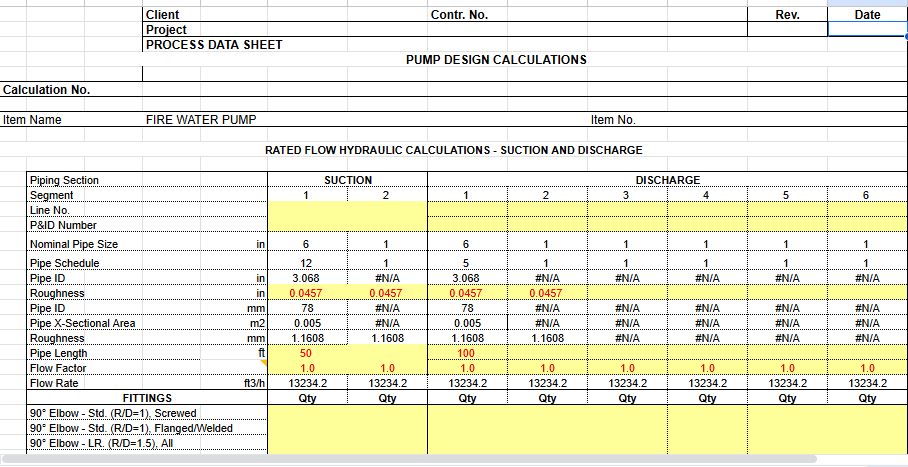

Centrifugal pump design calculations are essential for engineers to ensure optimal performance and efficiency of the pump system. These calculations involve determining key parameters such as flow rate, head, power requirements, and efficiency. Initially, the desired flow rate influences the impeller diameter and rotational speed, while the total dynamic head accounts for friction losses in the piping and elevation changes. The specific speed of the pump can also be calculated to identify the most suitable type of pump for the application. Additionally, materials must be selected based on the fluid being pumped to prevent corrosion and wear. By meticulously performing these design calculations, engineers can create a centrifugal pump that meets the operational demands while minimizing energy consumption and maintenance costs, ultimately leading to a reliable and effective pumping solution for various industrial applications.